The Process Manufacturing Suite for Acumatica by eWorkplace Apps is natively built within and is a integral part of Acumatica Cloud xRP platform and the Manufacturing edition. Developed within Acumatica’s framework and using the same database, the Process Manufacturing Suite for Acumatica enables all core business functions and process manufacturing operations to be connected, managed, and coordinated from one ERP system with a single source of truth.

Process Manufacturing Data Sheet

Get the brief of Process Manufacturing Suite for Acumatica developed by eWorkplace Apps. The solution is fully embedded with Acumatica’s manufacturing edition.

Industries We Serve

The Process Manufacturing Suite for Acumatica solution manages manufacturing complexities inherent to the products, processes, and variables of process- and formula-based manufacturing industries, such as:

Food & Beverage

Life Sciences / Pharmaceuticals

Packaged Products

Supplements / Nutraceuticals

Chemicals

Personal Care and Cosmetics

Paints & Coatings

Hemp and CBD

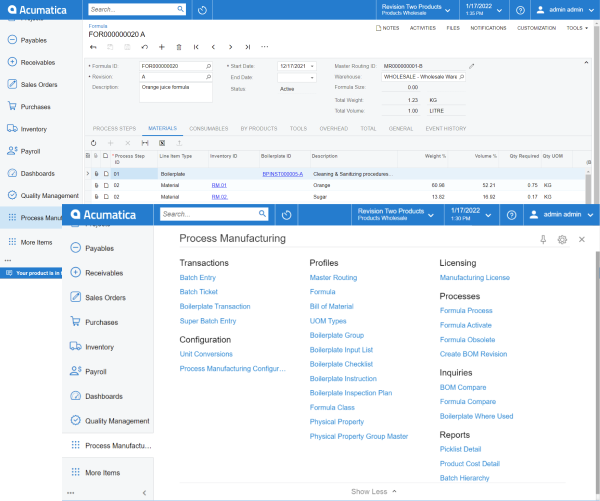

Comprehensive Process Manufacturing features natively built within Acumatica

Comprehensive Process Manufacturing features natively built within Acumatica

Key Benefits

Application Benefits

- Extends Acumatica to deliver an industry-specific ERP solution for process manufacturers

- Fully integrated with Acumatica Manufacturing Edition – MRP, Planning and Scheduling, etc.

- 100% developed using the Acumatica framework and database

Business Benefits

- Increase visibility and control

- Streamline operations

- Accelerate product development

- Balance inventory levels

- Scale up production

- Ensure quality and compliance

- Respond to changing customer demands

- Make better decisions, faster

- Strengthen your competitive advantage

Process Manufacturing Suite for Acumatica Features

Dynamically adjust formulas during both product development and production to meet specified target characteristics

Extend Acumatica’s Bill of Material for your process manufacturing needs. For example, define multiple packing configurations for the finished product made from the same formula.

Create and schedule the optimal number of batch jobs required for a product formula and its multiple packaging configurations.

Roll up existing and theoretical product costs, as well as fixed, tiered, and scalable costs, to formulas, intermediates, and finished goods during product development.

Quickly track and trace suspect materials from receiving through shipping, shipping back to receiving, or anywhere within WIP.

Stage and weigh up of materials that are going to be used in the production process with efficiency and accuracy.

Keep compliant with industry-specific and federal regulations, lot traceability reports, transactional audit reports, and shipping documentation.

Correctly manage and cost by-products

Integrate end-to-end quality control with the Quality Management Suite for Acumatica solution.

Create, manage, and distribute reports that improve transparency and decision making.

Define and track an unlimited number of physical and chemical properties. Modify or develop a new formula/recipe based on these properties and dynamically adjust

them to meet target characteristics.

Engage in product testing and development without interfering with current production and document testing notes to ensure consistency and quality.

Key Capabilities

- Gain more control over batch production of finished goods, including the by-products

- Manage QC activities and generate industry-specific compliance labeling and reports

- Create separate formulas and packaging specifications

- Dynamically adjust ingredients to meet target values of intermediates and finished goods

- Analyze costs and yields

- Safeguard formulas or recipes

- Support for manufacturing instructions and consumables

- Define and track losses at various levels

- Issue inventory to production based on those passed through QC

About eWorkplace Apps

Exclusively focused on the Acumatica platform, eWorkplace Apps provides industry-specific products, integrations, extensions, consulting services, and training that address the end-to-end business needs of discrete and process manufacturers and distributors. Our flagship products include Quality Management and Process Manufacturing for Acumatica. eWorkplace Apps offers Validation as a Service (VaaS), in compliance with FDA 21 CFR Part 11, as well as provides AWS based private cloud hosting services so that your environment is safeguarded once validated. Moreover, eWorkplace Apps delivers the comprehensive Advanced Planning and Scheduling Solution Powered by Siemens Opcenter to optimize the production planning and scheduling along with minimizing the downtime with enhanced customer experience.

Based in Aliso Viejo, CA, eWorkplace Apps is comprised of over 50 Acumatica developers, implementation consultants, and analysts with deep industry expertise to help optimize your business on the Acumatica platform.