Manufacturing businesses thrive to improve production efficiency and work continuously to achieve business goals. They seek ways to achieve manufacturing goals with minimal costs, maximum output while maintaining quality standards. For manufacturers, maximizing production efficiency is one of the primary goals. In this blog post, we will explore the following topics:

What is Production Efficiency?

Production Efficiency (PE) is utilizing resources with reduced costs and producing desired output. Manufacturers need to create a balance between quality, quantity, and resource utilization. It measures how well a manufacturing company can utilize the resources and produce goods at the lowest possible cost per unit without compromising quality. Manufacturing companies that implement strategies to improve production efficiency experience higher revenues.

How To Calculate Production Efficiency?

It’s important to measure production efficiency and take steps to improve production efficiency. Production efficiency can be measured using key metrics such as overall equipment effectiveness (OEE), yield rate, cycle time, capacity utilization, unit cost, throughput, and more. It provides accurate insights into the equipment’s efficiency, production capacity, asset utilization, costs, quality, and more.

Production efficiency is calculated by dividing standard output by actual output and multiplying it by 100. This will provide the percentage of the plant’s production efficiency. For example, a production unit is capable of producing 1000 units per day, but it is producing 500 units per day. So, 1000 units is a standard output, and 500 units is an actual output. The calculation will be:

Production efficiency = (500/1000) x100 = 50% efficiency rate

Measuring Production Efficiency

Production Efficiency % = Actual Output/Standard Output x 100

Production efficiency rate will allow manufacturing companies to identify areas of improvement and make informed decisions to increase production efficiency. Manufacturers should consider other metrics to improve production efficiency.

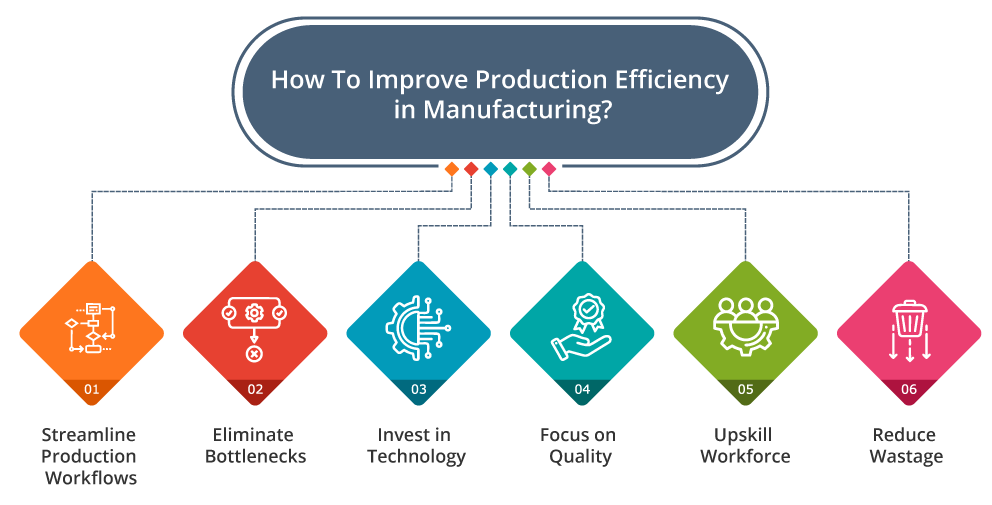

How To Improve Production Efficiency in Manufacturing?

1. Streamline Production Workflows

Manufacturers must evaluate the existing production line and analyze the production process. Analyze the current workflow and examine how many units are produced in a production line in a specific time period. Manufacturers must assess metrics such as machine utilization, capacity utilization, and more.

After examining, identify the potential areas of improvement and modify the procedures accordingly. Companies must set standard procedures for the production workflow to ensure consistency and improve operational efficiency. Document standard operating procedures (SOPs) to ensure the process is always aligned, and standards are being followed.

2. Eliminate Bottlenecks

Manufacturing companies should identify the bottlenecks and work towards eliminating them to increase productivity and reduces waste. Bottlenecks commonly arise from manual interventions or machinery breakdown. Manual bottlenecks include slow response time, not paying attention to details, and more.

Manufacturers should ensure to follow preventive maintenance practices regularly to prevent machine breakdowns. The bottlenecks slow down the process and affect production efficiency. Manufacturers must address these bottlenecks promptly to improve the process and achieve the output efficiently.

3. Invest in Technology

Investing in automation and technology can help manufacturing companies grow in an effective and efficienct manner. Automation allows manufacturers to streamline repetitive tasks, improve accuracy, and increase output, sometimes with a smaller workforce. In addition to automation, manufacturers must integrate ERP systems such as Acumatica that help to manage and track their entire production process.

Manufacturers can increase throughput and stay competitive by investing in advanced technology and automation. For example, say the machine loads with a 2-minute delay; it may not seem significant, but it adds up to 12.17 hours per year. If a company generates revenue of $5000 per hour, that’s a potential loss of $60,850 annually. Investing in upgraded technology can lead manufacturing companies, resulting in higher productivity and production efficiency.

4. Focus on Quality

Quality also plays a critical role in production efficiency. Along with producing products efficiently, it is essential for manufacturers to ensure the product meets specifications. Manufacturers must perform quality checks during the production process. Doing this can save time and money and reduces rework.

Implement a quality management system to ensure quality checks are done throughout the manufacturing process. Manufacturers must take immediate corrective and preventive actions if any deviations are found. Identify non-conformances, perform root cause analysis, take actions, and document the details to eliminate the defects in the future and drive continuous improvement.

5. Upskill Workforce

The productivity of the workforce is crucial for the success of manufacturing operations. A skilled workforce directly contributes to productivity and efficiency. Implementing machines and new technology doesn’t necessary a reduction in staffing but an increase in staff’s productivity.

Manufacturing companies must train employees to adapt to new technologies and methodologies. A trained workforce can identify issues at an early stage and act upon them quickly. For example, a trained employee may be able to anticipate a machine failure and initiate preventive maintenance to reduce downtime and imrpove production efficiency.

6. Reduce Wastage

Minimizing waste is crucial for achieving production efficiency and increasing productivity. Waste can include high costs, poor management, energy inefficiency, and excess material use.

By implementing lean manufacturing principles, manufacturers can identify and eliminate sources of waste. It can significantly lower the production costs and increase overall efficiency. Techniques such as Just-in-Time (JIT) production, Kaizen, waste audits, and utilizing advanced technologies like ERP systems can help reduce wastage. Manufacturing companies must consider following SOPs, reusing materials, and regularly measuring efficiency.

Productivity Vs. Efficiency

People often use productivity and efficiency interchangeably, while they are distinct concepts. Productivity is measured as the output relative to the input. If a company produces 1000 units/per day, then 1000 units/per day is the productivity of the company.

Efficiency, on the other hand, refers to producing goods while optimally utilizing its resources. If a company increases the production to 1100 units/per day utilizing the same resources, it is known as efficiency. While a company can be productive, it may need to be more efficient. Efficiency considers many factors, such as resources, costs, quality, and machine utilization. An efficient company aims to produce maximum output while minimizing waste and reducing the cost per unit of production.

Conclusion

By implementing these strategies, manufacturers can significantly enhance production efficiency. Achieving higher production efficiency will help manufacturers to reduce costs and position them to meet ever-evolving market demands. Manufacturers can leverage ERP systems like Acumatica with integrated quality management systems to improve their overall efficiency and ensure high-quality standards.

Contact Us

"*" indicates required fields